Material Categories

Explore our wide range of materials designed to meet your unique needs. While we’ve highlighted some of our most popular options, our capabilities extend far beyond this list. If you don’t see the material you’re looking for, contact us. We'll work with you to find the perfect solution.

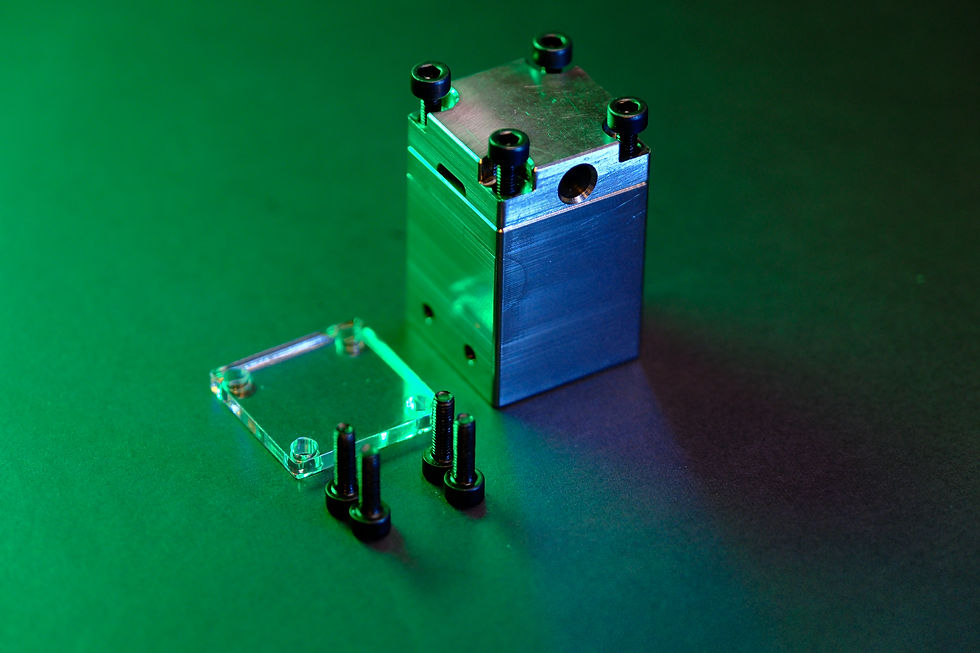

Metals

Aluminum

High strength-to-weight ratio, excellent corrosion resistance, and machinability make aluminum ideal for aerospace, automotive, and industrial applications.

1050, 1060, 2014, 5083, 5754, 6060, 6061, 6063, 6082, 7050, 7075, 7000, En AB 4700, 6062, 6068 T6, 2050 T84

Stainless Steel

Renowned for strength, rust resistance, and versatility, stainless steel is perfect for high-stress environments.

301, 303, 304, 304L, 310, 316, 316L, 318LN, 416, 420A, 420B, 420D, 440B, 440C, 15-5 PH, 17-4 PH

Brass

Offers excellent machinability and aesthetic appeal, suitable for precision parts and decorative applications.

C360, MS58, MS63

Titanium

Incredibly strong yet lightweight, titanium is widely used in aerospace and medical devices for its biocompatibility and corrosion resistance.

GR2, GR4, GR5

Copper

Exceptional electrical and thermal conductivity, making it essential for electronics and heat-transfer applications.

C10100, C14700, C14500

Tool Steel

Designed for high-wear applications like molds, dies, and cutting tools, ensuring long-lasting performance.

A2, A6, A8, 1.2363, 1.2516, 1.3501, 1.2550, D2, D3, 1.3520, 1.2419, 1.2367, 1.2379

Carbon Steel

Excellent machinability and weldability, ideal for construction and mechanical applications.

1010, 1018, S235JRC, 1020, C40, 1008, 1040, 1045, S265JR, S275JR, S355J2, C45, S355JR, 1215, API X65, 17.131

Nickel Alloys

Exceptional resistance to heat, oxidation, and corrosive environments makes nickel alloys ideal for aerospace and industrial applications.

Inconel 625, Inconel 718, Monel 400

Bronze

Highly durable with excellent wear resistance, commonly used in marine applications and decorative items.

Aluminum Bronze, Phosphor Bronze

Steel Alloys

High strength, toughness, and wear resistance; ideal for demanding mechanical, structural, and tooling applications.

4130, 4140, 4340, 42CrMo4, 41Cr4

Thermoplastics

General Use Engineering Plastics

Lightweight, strong, corrosion-resistant

POM-C, POM-H, Kestamid, PA, PA 6, PA 66, PE, PP, PET, PVC, PVC-U, HDPE, Ertacetal®, Ertalon®

Special Used Engineering Plastics

Lightweight, strong, corrosion-resistant

BASF Cellasto, PTFE, PVDF, PEEK, PMMA, PC, Divinycell® HCP50, Ertalyte®, FR-4

Composites

Carbon Fiber

Perfect for lightweight yet strong components in automotive and aerospace industries.

Manufacturing Capabilities

Rototip specializes in delivering custom manufacturing solutions to fit your unique needs. Whether you require prototypes or low-volume production, we ensure precision and quality every step of the way, offering a combination of over 10.000 materials, post processing treatments, and manufacturing methods.

All of Your Parts Come with 100% In-House Quality Control

High-Quality Post-Processes for Best Results

From surface finishes that enhance aesthetics to coatings that improve durability and custom treatments for specialized needs, our comprehensive post-processing services ensure your parts meet the highest standards. Explore our offerings below to see how we take your parts to the next level.

Coating

Protect and customize your components with durable and high quality coatings

Galvanizing

Anodizing

Powder Coating

Chemical Blackeninng

And more

Finishing

Enhance aesthetics and function with precise finishing techniques tailored to your parts

As-machined

Brushed

Bead-blasted

Polished

And more

Other

Optimize performance with our advanced treatments and personalized solutions

Laser-marking

Heat treatment

Painting

Insulations

And more

Multiple Materials, Multiple Processes: One Supplier!

Lorem ipsum dolor sit amet consectetur. Convallis convallis vulputate eget in diam. Viverra semper donec tempus lectus nunc. Pretium ornare netus tincidunt lacus. Quis id ornare mollis morbi.

-

Which industries you are active in?We serve a wide variety of industries, including: Aerospace, Aviation, Telecommunications: Tight-tolerance light components for aircraft and spacecraft. Industrial Automation & Machinery: Custom components for automation, factory robotics, and heavy machinery. Medical Devices: Custom parts that meet FDA and ISO 13485 standards for medical and healthcare applications. Automotive: Precision parts for electric vehicles and custom interior components.

-

How do I get a quote and place an order?Request a quote Login to our web app at app.rototip.com Enter your account details if you are logging in for the first time Go to the Request Quote page Upload your parts Adjust part specifics Review and submit your inquiry Approve a quote When you wish to proceed with an order, you can either approve the quote over our web app or share with us your purchase order. Production will be initiated in a few hours. Our team will carefully review your request and promptly provide you with a quote. You may also directly email our team at manufacture@rototip.com or urgent@rototip.com about your inquiries.

-

How do you handle intellectual property (IP) and confidentiality?Protecting your intellectual property (IP) is one of our top priorities. All customerfiles, designs, and communications are handled with strict confidentiality and are securely stored. We use encryption protocols to safeguard your data both in transit and at rest with only authorized personnel having access to sensitive information. Your designs are never distributed to more than a couple of engineers and operators who need to see the drawings because they will most likely be working on the production.

-

How do you ensure parts meet the quality requirements?We adhere to a quality management system that ensures every part meets the required specifications. Our process includes: Material supplier selection: We work with a select group of suppliers providing us the required materials in the right form and size. Depending on our history with each supplier, the materials we procure are tested for chemical composition, strength, hardness, and more. Selection of the machine and operator: Among all the workshops we work with, we work with and train an algorithm that awards the manufacturing of parts depending on the customer, material, geometry, tolerances, lead time, and quantity. Upon selection, our own engineers work with the operator throughout the production process from the initial CAM engineering to the deburring of the parts. Defining of quality control process & equipment: Together with our project managers and manufacturing engineers, our own quality engineers work out a detailed quality control plan specifying the following details, just to name a few: List of our quality equipment will be used during the process The percentage of parts that will be inspected visually, with caliper, with micrometers and other handheld devices, and/or on a CMM if any, list of measurements that cannot be measured Packaging: We operate with a detailed packaging guideline, clarifying how parts should be packaged, tagged, documented, and shipped. First Article Inspections (FAI): To ensure that the first part produced matches your exact design, we will ship you the first parts manufactured. Only after the client’s approval will we proceed with the production of the entire order. Final Inspection: All parts are inspected for dimensional accuracy, surface finish, and mechanical integrity before shipment. Certification Compliance: We possess ISO 9001 to ensure the highest levels of quality. Should you have any further questions, please drop us an email at quality@rototip.com.

-

What are your standard lead times?Lead times depend on the manufacturing process, material selection, and complexity of the part, among many others. For urgent inquiries and rather simple geometries, we offer manufacturing services as quickly as 2 hours. See below a table summarising our common offerings: Please contact us at manufacture@rototip.com or reach out to your account manager to discuss special requirements or other manufacturing technologies.

_edited.jpg)

_edited.jpg)